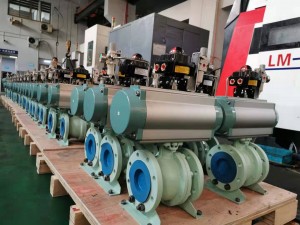

Twin seal plug valve

Twin seal plug valve

Main features: The plug is divided in 3 pieces: 1 piece of plug, 2pieces of segments that connected together by dovetails. During opening process, rotates the stem anticlockwise and pulls the slips away from the body through dovetails and the wedging action between the plug and segments, the clearance between the body and seals allows free movement without friction. Rotates stem further, with the tilt guide mechanism design, the plug will be turned 90°aligning plug port window to valve body bore that valve is fully opened. Because without abrasion between sealing surfaces, so the operating torque is very low and service life is longer. Twin seal plug valves are mainly used in CAA fuel storage plant, harbor refined oil storage plant, manifold plant, etc.

Design standard :ASME B16.34

Product range :

1.Pressure range :CLASS 150Lb~1500Lb

2.Nominal diameter : NPS 2~36″

3.Body material:Carbon steel, Stainless steel, duplex stainless steel, Alloy steel, Nickel alloy

4.End connection :RF RTJ BW

5.Mode of operation: Lever, Gear box, Electric, Pneumatic, hydraulic device, Pneumatic-hydraulic device;

Product features:

1.Dovetails Guided and lifted plug design;

2.Can be installed in any position;

3.No friction and abrasion between body seat and plug, low operating torque;

4.Plug is made by anti-wear material, with rubber lined on sealing area, having excellent sealing function.

5.Bidirectional seals, no limitation on the flow direction;

6.Spring loaded packing can be chosen;

7.Low emission packing can be chosen according to ISO 15848 requirement;